Delivering a successful commercial fit-out requires precision, foresight, and an understanding of how businesses actually operate. Electrical systems in commercial spaces are the unseen backbone of daily activity—powering lighting, equipment, data networks, and life-safety systems. When designed and installed correctly, these systems become invisible in their reliability. When done poorly, they cause endless frustration, downtime, and cost. At EDL Electrical, we treat every fit-out not simply as an installation but as a complete performance system designed for safety, efficiency, and longevity. From boutique shops and cafés to multi-studio offices, our work ensures that every circuit, fitting, and data run aligns with how people really use the space.

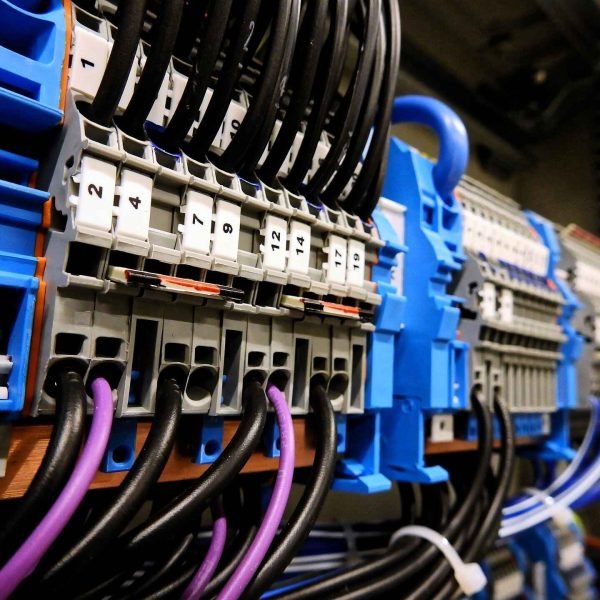

A well-executed commercial fit-out begins with clear organization and transparency. Electrical distribution boards are laid out methodically and labelled so that anyone—from maintenance teams to future contractors—can identify circuits instantly. Each board includes spare ways for expansion, allowing the client’s business to grow without reworking the entire system. Lighting is chosen not just for brightness but for its ability to create mood and highlight what matters. In a retail environment, this means light that flatters merchandise and enhances customer experience, while in cafés or studios it means illumination that’s bright enough for productivity but gentle on the eyes and energy bills. Emergency lighting is another critical component. It’s designed according to proper risk assessments, tested rigorously, and logged so that compliance is documented, not assumed. Power and data systems are then aligned with workflow—tills, prep areas, and workstations are powered precisely where needed, with containment that’s both safe and tidy.

Our process always begins before a single cable is installed. During the pre-construction stage, we collaborate closely with architects, designers, and project managers to make sure every technical detail supports the design intent. Our design coordination reviews include assessing drawings for power densities, ceiling heights, lighting uniformity, potential glare, and emergency escape routes. This phase identifies potential clashes early, preventing costly delays later. We also carry out load studies to confirm that the existing supply has sufficient capacity for the intended use. If it doesn’t, we provide practical solutions such as phased board strategies or sub-main upgrades, ensuring that each phase of occupation or expansion remains safe and manageable.

Value engineering is another key service we bring to every project. Our goal is to achieve the desired concept within budget, without compromising safety or aesthetics. We analyse specifications and recommend alternative fittings, cable types, or control solutions that reduce cost while maintaining or even improving performance. For instance, selecting LED fittings with high colour rendering but lower wattage can reduce both installation and long-term energy costs, while simplifying the maintenance burden. This proactive approach to specification not only saves money but also ensures consistency and reliability across the site.

When the installation phase begins, attention to detail continues on site. Our teams maintain clean, well-organized workspaces and coordinate carefully with other trades. We understand that commercial projects often operate under tight deadlines, with opening dates already advertised or tenants ready to move in. We therefore plan meticulously to keep electrical works ahead of schedule and responsive to evolving site conditions. Every termination is torque-tested, every cable neatly dressed, and every luminaire positioned precisely to achieve the design’s intended effect. The final presentation—neat containment, accessible panels, and clearly documented circuits—reflects our belief that good electrical work should be as elegant behind the walls as it is visible to the eye.

At handover, clients receive a complete and professional documentation package that ensures compliance, clarity, and traceability. This includes all Electrical Installation Certificates (EIC) or Electrical Installation Condition Reports (EICR) as applicable, along with circuit schedules and distribution board charts. Emergency lighting systems are accompanied by test logs, luminaire locations, and a clear plan of test points to streamline future inspections. As-built drawings are provided in both PDF and CAD formats, capturing any on-site variations so that future contractors have an accurate record to work from. We also include a comprehensive Operation and Maintenance (O&M) manual detailing equipment warranties, supplier contacts, and recommended service intervals. By providing this level of documentation, we give clients complete visibility and confidence in their installation.

The completion of a fit-out is only the beginning of a system’s life cycle. To protect that investment, we offer Planned Preventative Maintenance (PPM) packages that are tailored to the specific needs of each site. These packages are not generic “box-ticking” exercises—they’re designed to actually prevent downtime and maintain performance over the long term. Quarterly visits include visual inspections, functional testing, and any small remedial works that can be completed immediately. Once a year, a more detailed review is carried out: emergency lighting undergoes its full three-hour duration test, distribution boards are opened for thermal imaging or torque checks, and test results are compared against previous readings to identify trends before faults develop. Every five years, or as required by local authority licensing or insurance, a full EICR is performed to confirm ongoing compliance with the IET Wiring Regulations.

Reactive maintenance is handled with equal professionalism. We offer agreed service level agreements (SLAs) for call-outs, ensuring that urgent issues—such as tripped circuits, lighting failures, or damaged containment—are attended to quickly and efficiently. Our vans are stocked with common spares, allowing many issues to be resolved on the first visit. For multi-site clients, we maintain a database of their assets and past service records so that recurring issues can be tracked and addressed systematically. This level of organization minimizes disruption and ensures that facilities teams always know the exact status of their electrical infrastructure.

Timelines and budgets are communicated transparently from the outset. For smaller retail or café fit-outs, electrical works typically take between one and three weeks from shell to trade, depending on the complexity of lighting, power density, and data requirements. Studio and office CAT-B fit-outs—where interiors are customized for specific tenants—usually run between two and six weeks, depending on size and design complexity. Maintenance costs are equally straightforward. PPM packages generally range from £45 to £85 per element per visit, with bundled plans offering cost efficiencies for larger portfolios. This predictable pricing structure allows businesses to plan ahead without surprises or hidden charges.

Our experience across West London illustrates what “good” looks like in real-world settings. In a boutique on Chiswick High Road, we implemented a 3000K LED lighting system with a high Colour Rendering Index (CRI) to showcase fabrics at their most vibrant. The store now benefits from adaptive scene control that shifts between bright, energetic daytime lighting and a warmer evening ambience for events or late openings. The result was a 40% reduction in energy consumption alongside an improved shopping experience. In Hammersmith, we completed the electrical fit-out of a busy café, where reliability and hygiene were paramount. The design included resilient kitchen supplies, IP-rated fittings in back-of-house areas, and simple, intuitive lighting controls that staff can operate without technical training. Every circuit was labelled, tested, and certified before handover, ensuring the owner can manage maintenance independently.

At a production studio complex in Brentford, we provided a highly technical installation involving sub-mains distribution to individual edit bays, structured data cabling to racks, and low-glare task lighting designed for video work. The environment now runs cool, quiet, and flicker-free—an essential requirement for both comfort and sensitive audio-visual equipment. This project demonstrated how commercial electrical design must balance technical performance with user experience, delivering systems that support creative work without distraction or heat buildup.

Our approach to commercial projects is built on partnership. We recognize that every business has different operational priorities—some require after-hours work to avoid disrupting trading hours, while others need completion in tight construction windows. We routinely schedule night or early-morning shifts to meet deadlines, coordinating with site managers and neighbours to minimize noise and traffic disruption. For multi-site operators, such as retail chains or hospitality groups, we can centralize coordination so that one point of contact oversees all scheduling, reporting, and invoicing. This level of administrative simplicity saves clients time and ensures consistent standards across every property.

Planned maintenance provides long-term benefits that go beyond compliance. Regular inspections identify early warning signs of overheating, insulation degradation, or overloaded circuits before they cause damage. Emergency lighting systems are kept fully functional, ensuring safety for staff and customers alike. Well-maintained installations also reduce insurance premiums and extend the lifespan of expensive equipment, delivering measurable returns over time. Moreover, predictable servicing helps businesses avoid the reputational damage and operational chaos that can follow unexpected electrical failures. A well-lit, smoothly running environment not only keeps customers and staff safe—it enhances the overall impression of quality and professionalism that clients associate with the brand.

Technology continues to evolve, and we make sure our maintenance practices evolve with it. LED drivers, DALI controls, and smart monitoring systems can now be interrogated digitally to identify faults remotely. We provide upgrade paths for legacy systems, allowing older installations to benefit from new energy-saving controls or wireless reporting without wholesale rewiring. Sustainability is built into our ethos; we specify fittings with long lifespans, recyclable components, and serviceable parts. When clients choose to refresh their interiors or update lighting schemes, we help repurpose or recycle equipment responsibly, reducing environmental impact.

Every completed fit-out and maintenance plan represents a long-term relationship, not a one-off transaction. From the first site visit to ongoing support years later, EDL Electrical provides continuity, professionalism, and accountability. Our clients know that every cable, connector, and control module has been installed to the highest standards and documented for future reference. That reliability translates directly into peace of mind—business owners can focus on operations, knowing their electrical systems are both compliant and future-ready.